Mori-Say Multi-spindle Lathes

MORI-SAY Multi-spindle Lathes

MORI-SAY AC series

Cam-controlled turning lathes for medium to high volume turning. Available in 6 or 8 spindles, AC series with variable feed & speed spindle motors

Fully CNC MORI-SAY TMZ series

CNC controlled Multi-spindle Lathes available in 5, 6 and 8 spindles. Suitable for small to high volume production and the capability of machining difficult and complex components

Improve Your Productivity

View Mori-Say Products

Multi-spindle Automatic Lathe MORI-SAY 620AC

Basic configuration with 6 transversal, 6 longitudinal saddles and 4 cross saddles. Siemens Simodrive motors with continuous regulation. Possibility of machine modification for spindles stop – the 620SAC configuration. Possibility of machining diameters up to 20mm.

Multi-spindle Automatic Lathe MORI-SAY 632AC

Basic configuration with 6 transversal, 6 longitudinal saddles and 4 cross saddles. Siemens Simodrive motors with continuous regulation. Possibility of machine modification for machining of 42 mm maximal diameter – the 642AC configuration. Both models can be modified for spindles stop – the 632SAC and 642SAC configuration.

Multi-spindle Automatic Lathe MORI-SAY 657AC, 667 AC

Basic configuration with 6 transversal, 6 longitudinal saddles and 4 cross saddles. Siemens Simodrive motors with continuous regulation. Possibility of machine modification for machining of 67 mm diameters – the 667AC configuration. The 657AC model can be modified for spindles stop – the 657SAC configuration.

Multi-spindle Automatic Lathe MORI-SAY 832AC, 842AC

Basic configuration with 8 transversal, 8 longitudinal saddles and 4 cross saddles. Siemens Simodrive motors with continuous regulation. Possibility of machine modification for machining of 42 mm maximal diameter – the 842AC configuration. Both models can be modified for spindles stop – the 832SAC and 842SAC configuration.

Multi-spindle Automatic Lathe MORI-SAY TM620CNC

Six-spindle fully CNC-controlled automatic lathe of high accuracy, rigidity and speed. It is designed for mass and serial production of precision components from bar material up to a maximum of ø 20 mm (ø 24 mm). High productivity is enabled by a total of 21 CNC-controlled axes and another 13 available for special accessories and 6 spindles with a maximum speed of 6,000 rpm. Spindle drum indexing: 0.7 s. The Fanuc i30-B plus control system and two operator panels ensure comfortable and friendly machine operation.

Multi-spindle Automatic Lathe MORI-SAY TMZ518CNC

Basic configuration with 5 cross saddles. TM configuration – up to 24 controlled axes and synchronous speeds of spindles. TMZ configuration – up to 30 controlled axes and independent speeds of the spindles. Integrated automatic bar magazine. Control system and motors: Fanuc

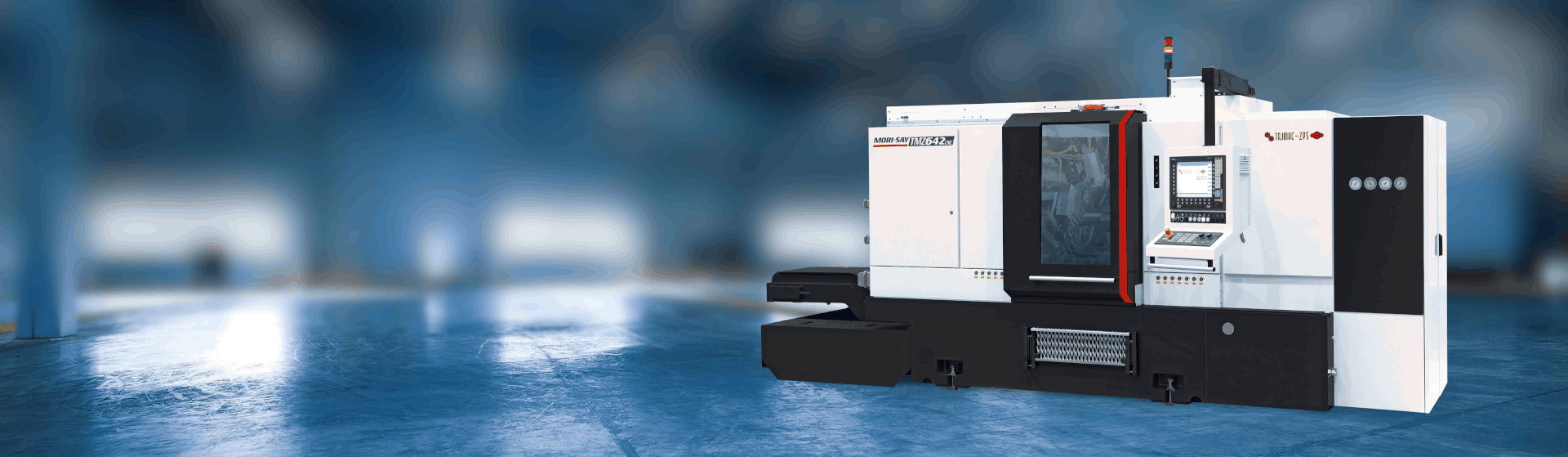

Multi-spindle Automatic Lathe MORI-SAY TMZ642CNC

The Mori-Say TMZ 6-42 CNC offers very high processing flexibility and fast changeover with the ability to drop a variety of complex precision parts complete, as either a bar-fed or chucker operation. Across the spindles, a wide variety of precision metalcutting operations can be accomplished very quickly and without handling

Multi-spindle Automatic Lathe MORI-SAY TMZ842CNC

Basic configuration with 7 cross saddles, 8 longitudinal saddles and 1 parting-off slide. Up to 56 numerically controlled axes, independent speeds of the spindles. Siemens Sinumerik 840D sl control system, Simodrive motors.

Multi-spindle Automatic Lathe MORI-SAY TMZ867CNC

With its cast iron base built to high European standards this machine is the most robust and rigid machine in the market place weighing in at 20 tons. Combined with the highest spindle torque in the industry, this machine can handle the toughest of materials with accurate precision and reliability.